Unmatched baler safety: We keep operators safe

Advanced safety in every aspect of our machinery

The European safety regulations (EN16500 safety standard) provide detailed guidelines for the production of vertical balers. To meet these standards, all Bramidan machines incorporate advanced safety features and undergo testing to ensure compliance with the European regulations.

Our machines are designed with following features to meet the highest European safety standards:

1. Secure operation

2. Redundant safety checks

3. Controlled opening with spindle

4. Safe bale ejection

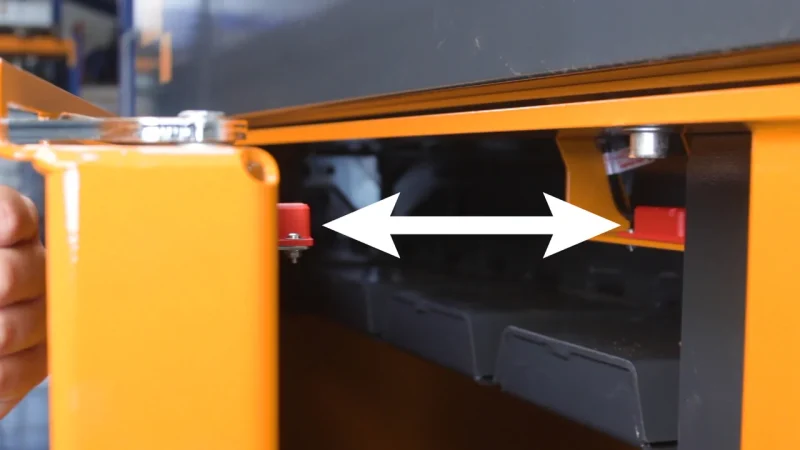

5. Two-button operation for ejection

6. Controlled ejection speed

7. Optimised for minimum noise

Businesses and teams worldwide trust in our equipment

At Bramidan, we understand that safety and usability go hand in hand. That’s why the highest level of safety is the foundation of our baler design and production.

When you invest in a Bramidan baler, you’re choosing a reliable, safety-first solution you can trust. Our balers not only meet the strict EN16500 standards but also surpass ANSI and OSHA requirements, ensuring secure baling every time.

With user safety as our top priority, our machines are engineered with intuitive controls and robust protective features. This allows operators around the world to work confidently and efficiently, knowing they can rely on Bramidan for safe waste management.

Key elements of the EN16500 standard include:

- The baler only operates when the door is securely closed. This feature is designed to eliminate the risk of accidents during operation.

- A dual-check mechanism for malfunctions, the door switch is designed to prevent open door operation. In case of failure, a backup control unit steps in to prevent operation.

- A strong spindle mechanism is required for controlled opening of the main door to prevent it from opening too fast and causing injuries.

- Safe two-handed operation for bale ejection, which prevents tampering and ensures that bales can only be ejected with precise simultaneous button presses.

- Controlled ejection speed to prevent the bale from tumbling, thus avoiding potential injuries or damage.

- The noise level during operation must be as low as possible to maintain a good working environment.

The standard covers balers that are manually or mechanically fed and include fixed enclosed baling chambers with compacting equipment that may be mechanically, hydraulically, or pneumatically operated. It also includes the requirements for manual unloading or mechanical ejection of the compacted bale. Notably, the standard applies to integrated mechanical feed equipment forming part of the baling press assembly.

“I use this baler to compact cardboard. It’s easy and it’s safe. I feel nothing can go wrong.”

— Mr Hans Lautrup, Sales Assistant, Rema 1000

Fill in the form and we will contact you

Questions? Contact us today