OTHER PRODUCT

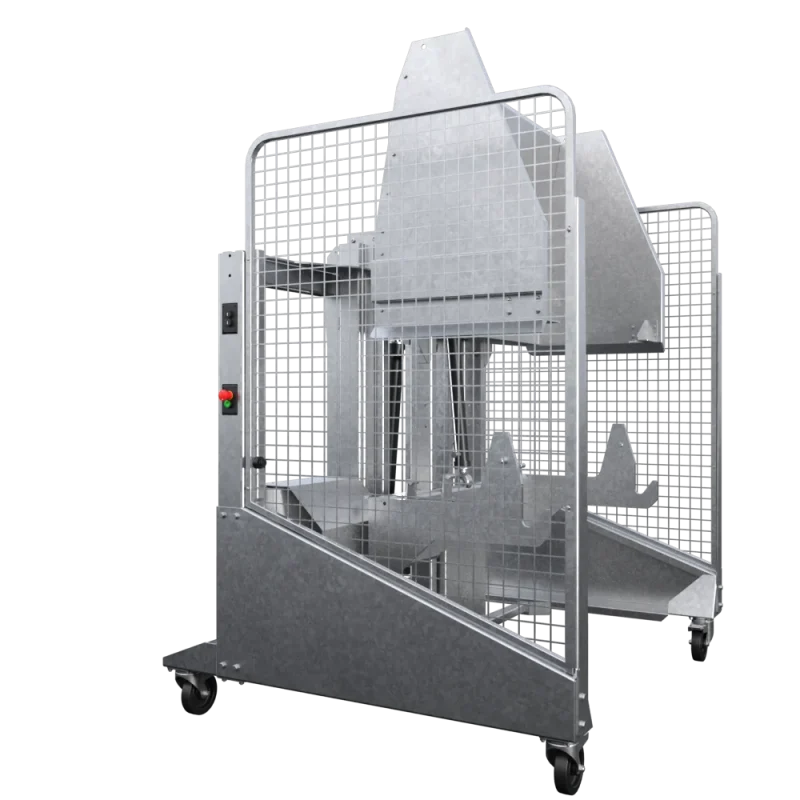

Tipping system CT

The tipping system can be used for emptying different sizes of containers into your compactor or onto a conveyor belt. The system can be adjusted to different tipping heights.

Choose between a stationary model with feet or moveable with wheels.

Add to your quote

OTHER PRODUCT

Tipping system CT

Quote details

OTHER PRODUCT

Tipping system CT

Overview

How to operate

Safety

Technical specifications

Efficient emptying of bins

Flexible tipping and emptying systems for standard plastic bins.

Individual solutions

With three different models and different options, you can get a tipping system that suits your individual needs.

Tipping System – for emptying waste bins:

- For standard bins

- Fixed- or swivel wheels or stationary legs

- Tipping height between 1600-2500 mm

- For bins up to 1100 litres

- User panel can be placed on the right or left side

- Durable design – strong steel construction

- Hydraulic cylinders

- Safe in use

How does the CT tipping system work?

Galvanized tipping system for easy waste handling

- Place your bin or container in the lifting section.

- Flexible system – for containers with and without trunnions.

- Use the two-handed operation to tip the bin or container.

- Remove the empty container.

The CT tipping system is safe and easy to operate

Our equipment has the highest level of safety – don’t settle with less!

| Power supply | 1x230V 50Hz 10A |

| Motor (kW) | 1.1 |

| Noise Level (dB) | 65-68 |

| Cycle time avg. (sec) | 57-75 |

| Dimensions WxDxH (mm) | 2100 x 2510 x 4600 |

| Weight (kg) | 1000 |

| Tipping height (mm) | 1670-2570 |

| Load capacity (kg) | 400 |

Save money and reduce your CO2e with BRA-IN

Recycling is essential for the environment, and BRA-IN makes it easier. This intelligent waste management solution monitors, analyses, and optimises your operations to help you save costs and reduce emissions.

BRA-IN (short for Bramidan Intelligence) connects all your compaction equipment through a user-friendly IoT platform. It provides a complete 360-degree view for more intelligent waste and recycling management.

Heading for loop

Our quiet machines mean a safer working environment

Most balers operate at a noise level of around 70-80 dB.

Bramidan balers are a much quieter alternative. To put this into perspective, a 10 dB reduction makes a significant difference – comparable to moving from the noise of a busy street to the calm of a quiet office. A lower noise level plays a crucial role in creating a safer and more comfortable working environment.

30dB

50dB

75dB

100dB

160dB

CT

65-68 dB

Whisper

Refrigerator

Other balers

Cars on highway

Turbojet engine

FAQ

OTHER PRODUCT CT

Most Common Questions & Answers

What is your warranty period?

We offer a 12-month warranty period as standard on all machines.

What is the delivery time for a machine?

We are a modern company that is order-producing, but we have a minimum stock of machines for delivery to our regular customers within 2-3 weeks. Contact your local distributor to hear the fastest delivery time.

Can I use a tipping system if I have containers without wheels?

Yes, you can. We offer tipping systems with wheels so that you can lift your stationary plastic containers and bring them to your compactor. The wheels come in a fixed or flexible version and are equipped with brakes for your safety.

What container sizes can I use in a tipping system?

Our tipping systems are for standard plastic containers between 370 litres and up to 1100 litres.

Did you find an answer to your questions? If not visit our FAQ universe.

EXPLORE FAQFill in the form and we will contact you

Questions? Contact us today

Global sales

Global BRA-IN